站点设定

产品

功率

变压器

汽车

资源

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

视频库

Cx Family Common Mode Chokes

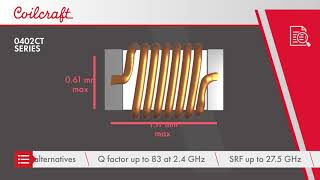

0402CT Low Profile Chip Inductors

XAL7050 High-inductance Shielded Power Inductors

XGL4020 Ultra-low DCR Power Inductors

Student Support

Learn more about magnetics, request free samples or ask our engineers a question.

Get Support

Quality

安全认证

(1)

(1) (2)

(2) (3)

(3)

(4)

(4) (5)

(5) (6)

(6)

(7)

(7)