사이트 설정

제품

전력

트랜스포머

자동차용

리소스

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

모델 및 레이아웃 도구

비디오 라이브러리

Cx Family Common Mode Chokes

0402CT Low Profile Chip Inductors

XAL7050 High-inductance Shielded Power Inductors

XGL4020 Ultra-low DCR Power Inductors

Student Support

Learn more about magnetics, request free samples or ask our engineers a question.

Get Support

품질

안전 인증

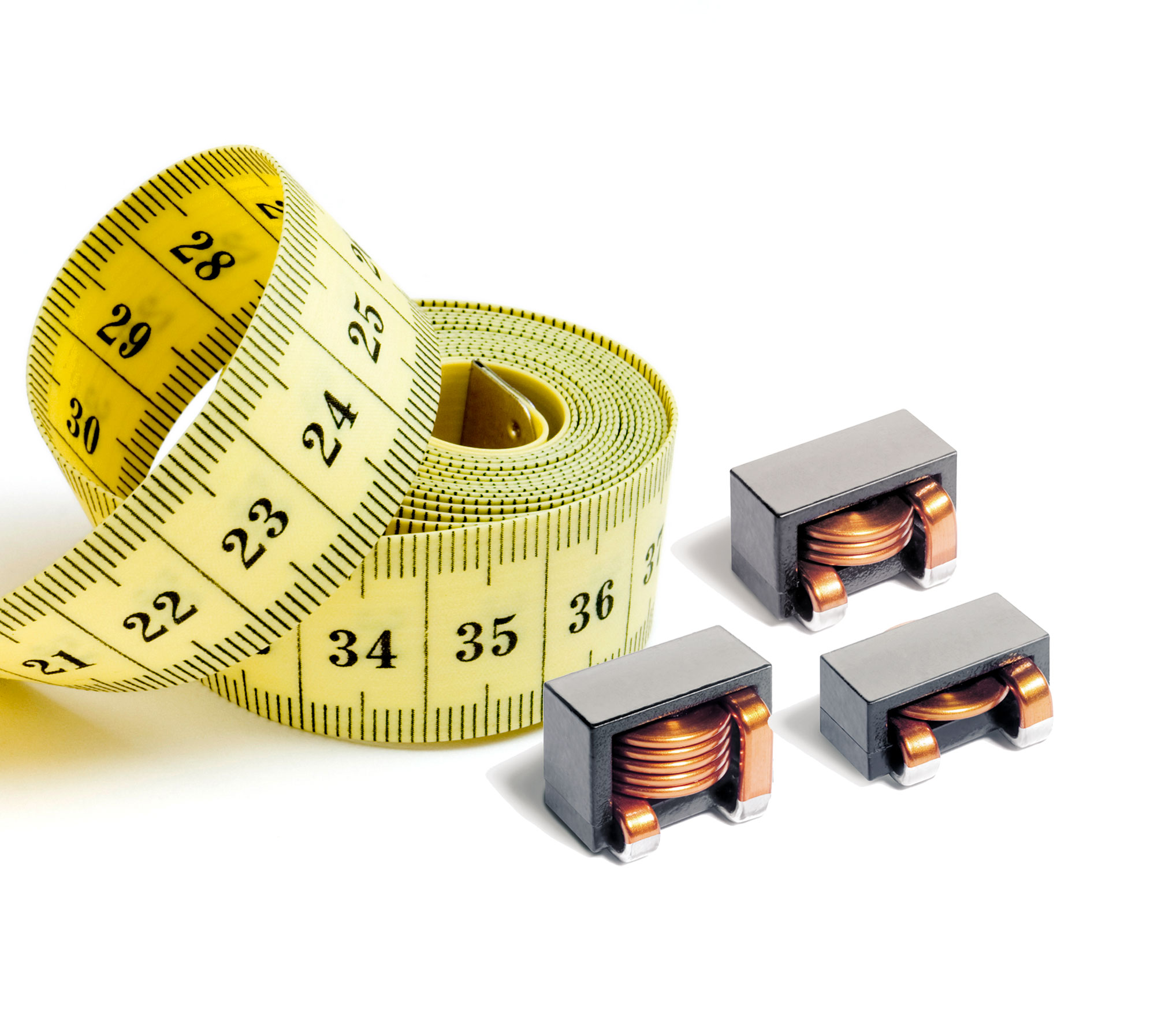

Figure 3. Molded inductors are mechanically rugged and magnetically shielded for use in high density circuits

Figure 3. Molded inductors are mechanically rugged and magnetically shielded for use in high density circuits