사이트 설정

제품

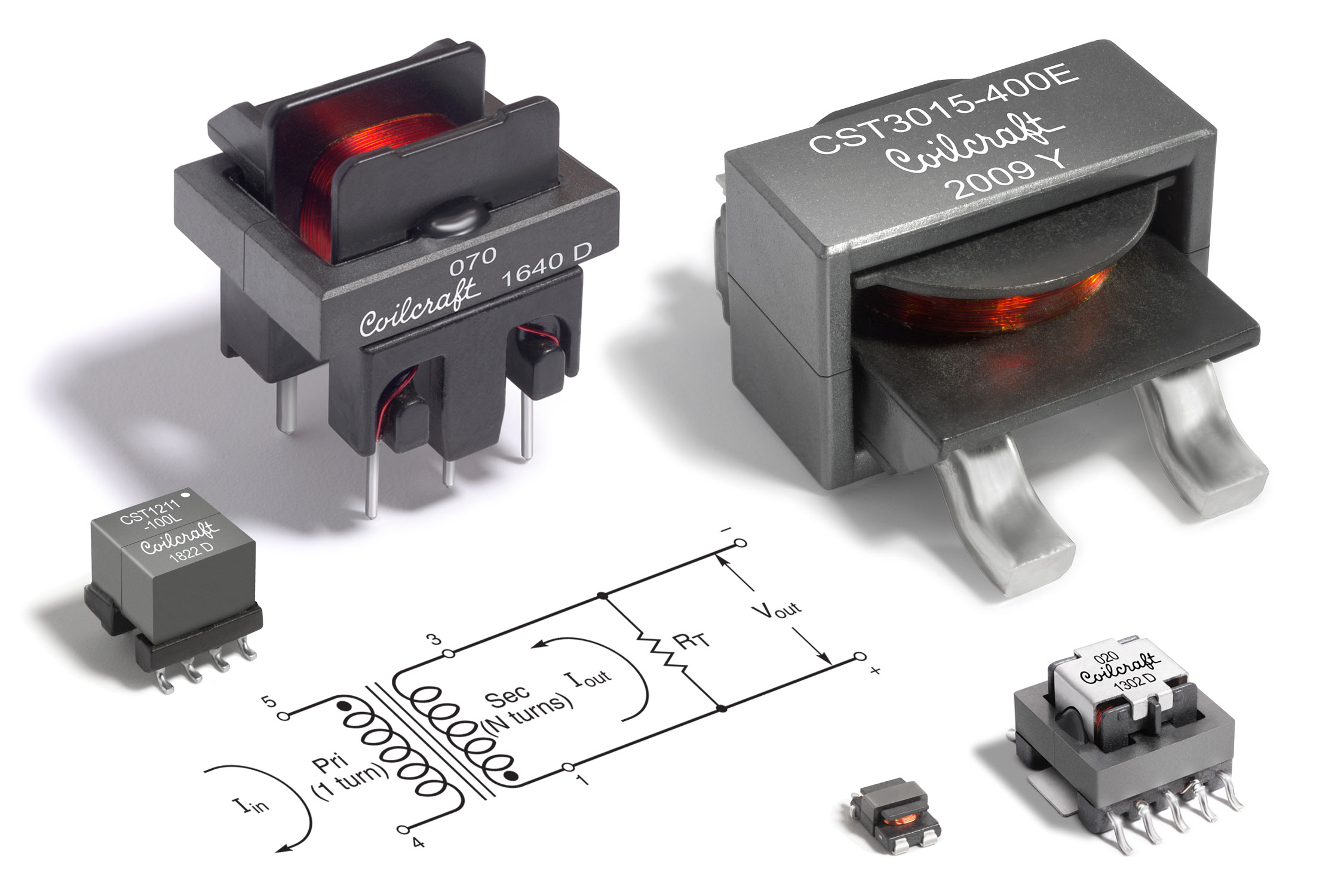

전력

트랜스포머

자동차용

리소스

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

![YouTube preview image]()

모델 및 레이아웃 도구

비디오 라이브러리

Cx Family Common Mode Chokes

0402CT Low Profile Chip Inductors

XAL7050 High-inductance Shielded Power Inductors

XGL4020 Ultra-low DCR Power Inductors

Student Support

Learn more about magnetics, request free samples or ask our engineers a question.

Get Support

품질

품질 인증

안전 인증